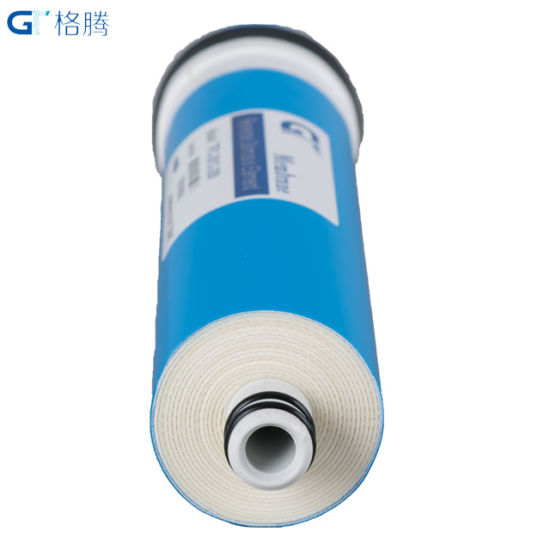

WHAT IS OUR "DRY" MEMBRANE? WHAT ADVANTAGE DOES IT PROVIDE?

By "Dry" membrane, we mean the membrane as received from the manufacturing area. The membrane has a modest amount of retained moisture and a residual amount of material that functions as a wetting agent. The wetting agents hold the water in the membrane very tightly to prevent easy drying and collapse of the membrane. The "as manufactured" membrane is very clean and nearly sterile. By careful manufacturing we can keep exposure to the environment to a minimum. The finished element has a minimum amount of free liquid, lower bacteria and mold exposure, a less hospitable growth environment, and a strong resistance to further moisture loss. All of these factors result in a much improved shelf life for the finished element. Under ideal conditions of storage, two plus years is reasonable. Since the element does not contain excess water, it is lighter and therefore less expensive to ship and more resistant to freezing. To summarize the advantages:

LONGER SHELF LIFE MORE RESISTANCE TO FREEZINGLESS EXPENSIVE TO SHIPLESS HANDLING AND TESTING = LOWER COSTWHAT DISADVANTAGES COME WITH "DRY" MEMBRANE?

Dry membranes can be integrity tested using air, but they can not be performance tested without losing the benefits summarized above. We handle the above disadvantage by doing sample testing and using statistics to give reasonable assurance of lot performance. The elements that are used in the wet testing procedure would be handled like standard product that does not need extended shelf life. The other disadvantage that comes with no wet testing is the transfer of that rinse time from our facility to the customer's facility. In the process of testing an element, it will typically have a minimum of 30 minutes flush time before data is taken. Low productivity elements need about that much time to rinse down to our minimum TDS rejection standards. High performance membrane equilibrates much faster, and does not present any unreasonable delay in reaching TDS standards. In practical terms, the high productivity spirals will not require any additional time over what is currently done to performance test a system. Low productivity elements may need 30 minutes more test time. Higher test pressures can lessen extended test time requirements, as well as lower TDS feed water or additional pre-rinse time. To summarize disadvantages:

LONGER SHELF LIFE MORE RESISTANCE TO FREEZING